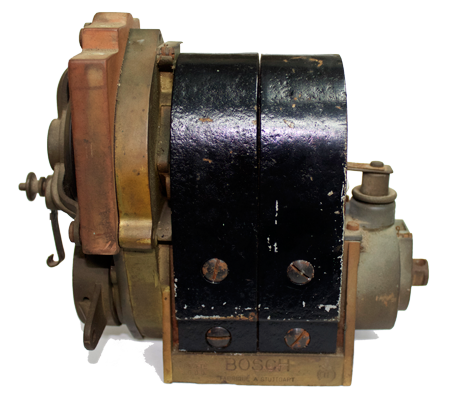

There is a huge variety and we have done most of them. ( Including Lucas, Bosch, BTH, EIC, Thomson Bennett, ML, Splitdorf, Saga, Dixie….)

We have spares for many and generally can find most components required, in an overhaul, from stock or donor units on the shelf.

We can handle all of the typical multi cylinder types Including Bosch, Simms Eisemann Lucas BTH Marelli, Dixie, Mea, IH, Wico etc.

As with the motorcycle mags, there are quite a few parts available reproduction such as pickups and slip rings etc, whilst others parts can be sourced second hand or made from scratch if required.

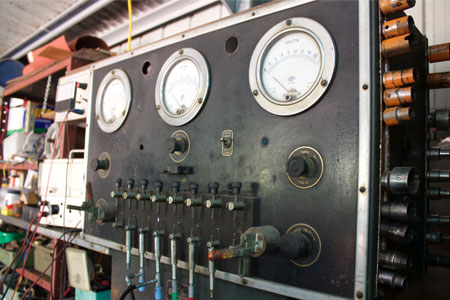

There is a large amount of interest in veteran types and we have done all the common single and V-twin magnetos for this era. Our automotive test bench is really valuable in ensuring that the V twin types are firing at the correct timing, not only at low speed but across the range. There is often quite a bit of wear in the cam holding assemblies on early Bosch types, not to mention the penchant for some owners to “improve” the advance retard range (to anything up to 50 degrees …. and 50 degrees magneto meaning 100 degrees crankshaft!!). This all needs to be taken care of, in order to return the magneto to a useable condition.

We are frequently asked to reverse the running direction and change the firing angle of a v twin magneto; without the right test equipment it’s very hard to do the job properly. With a rotating spark gap on the test bench, it becomes a relatively simple matter to “tweak” the cam position in order to correct timing inaccuracies, once other sources of timing error have been eliminated.

Many british twins in the twenties and thirties ran Lucas and Thomson Bennett Magnetos; this includes ACV, MDV, MNV KNV and KLV types. Cam rings are readily available for the most common of these and slip rings can generally be adapted as necessary.

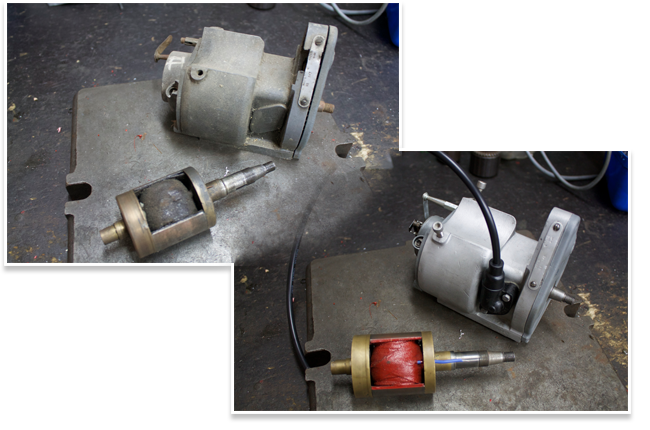

As a general principle, overhauling a Magneto involves repairing and restoring the device to its original level of performance.

The key components are the armature or coil, the condenser, the bearings, points plate pickups and distributor, if it is a multi cylinder magneto.

The heart of any magneto is the coil. It is imperative that utmost care is taken in its construction. We construct our coils with quality materials which confer excellent insulation and breakdown resistance. All coils are vacuum impregnated with electrical varnish to prevent ingress of moisture and protect the very fine wire from vibration.

Unless by prior arrangement, we do not undertake plating of parts to restore cosmetic appearance to original standard. In general all items are cleaned and bead blasted and painted where appropriate. Any parts that are replaced are typically zinc plated or stainless in the case of screws and small fittings.

To undertake full cosmetic restoration involves the complication of involving outside vendors, with increased lead times, and, especially in the case of plating, lost damaged or poorly finished parts. It is realistically very difficult to manage and we prefer owners who want concourse cosmetics to have such work done on critical parts before sending for repair.

In some cases the opposite situation exists. When a magneto or Dynamo is from and older restoration or indeed a totally unrestored vehicle, we are able to do a full internal restoration without significantly altering the external appearance of the device.

Apart from remagnetising, one of the final steps is of course the test bench. It is really important, especially on twin or multicylinder magnetos, that spark timing is checked on a rotating spark gap. Whilst point openings and protractors may indicate where the points appear to open, it is only on the rotating gap that accurate timing can be measured.

In particular, erratic sparking or timing drift that may occur at higher speed can readily be seen. This test really highlights deficiencies and instability in the points mechanism which on a plain spark gap are not at all obvious.

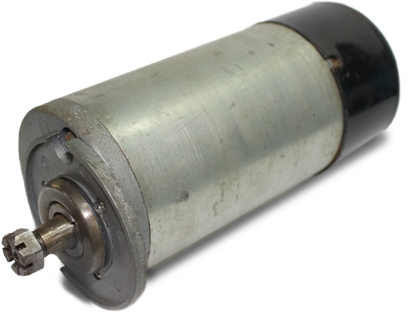

We can carry out conversion of early 3 brush dynamo to 2 brush operation to overcome the problem of over and undercharging and improve battery life. With an electronic regulator hidden under the seat or inside a toolbox, the conversion can generally be done without obvious external deviation from originality.

The larger Lucas and Autolite units can be converted to 12V operation if requested. We do not recommend conversion of the smaller Lucas, miller and splitdorf units as the output available does not warrant the change.

Our conversion includes rewinding of both armature and field coil so that the dynamo reaches cut-in voltage at the normal rpm and there is not excessive wastage of power heating up the field coils at low rpm. We do not recommend fitting a 12V regulator to a 6V dynamo for this reason, especially in Australia where ambient temperatures can be quite high. Any time the engine revs fall below about 1600 the 6V field coil is expected to cope with up to 4 amps at 13V, which it was never designed to do.

It should also be noted that the Lucas E3L generator when converted to 12V will still be limited in output due to the fact that there is no cooling fan.

Our experience shows that machines running electronic ignition and also using the headlight for day running will be limited to 35W headlamp to avoid throwing the solder on the armature. This may sound conservative, but about 7Amps continuous output (100W at 14V), is all you can realistically expect from the 60W Lucas original. With the 35W headlight, tail light and instruments pulling 4amps, ignition 2-3 amps, you do not have much left to charge the battery.

Other than running electronic ignition, I don’t see many other major reasons for switching to 12V operation. It is true that there is a much wider selection of quality batteries in 12V in a range of sizes, so this can be a factor. However, many machines would show a big improvement if strict attention is paid to wiring and condition of switches and connections. It is amazing how much difference fitting relays to the headlight of a 6V motorcycle can make. We do have a source of automotive grade 6V relays for those who wish to make this upgrade. A big benefit is that the headlight current no longer has to route through the dipper switch, which itself can be the source of significant losses.

In addition to the above repairs we also stock Electonic regulators for dynamos, both positive and negative earth; 6 and 12 Volt.

We stock 12V regulator rectifiers for permanent magnet alternator control. These units are robust and suit both single phase and three phase alternators. They can be used to convert early 3 wire alternators to 12V operation.

The zener diode system was never successful at controlling the charging system voltage. The zeners used don’t start to bypass significant current until battery voltage exceeds 15V and modern batteries just will not tolerate being constantly overcharged.

You can leave the zener in place with dummy wiring for appearance of originality; but if you want reliability and good battery life, then the regulator rectifier is the only way to go.

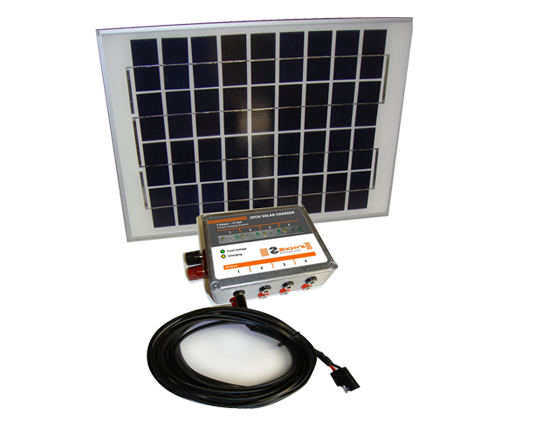

The control unit has four independent outputs for trickle charging of batteries. It is powered by a single solar panel. For classic bike owners each output can be selected to 6 or 12V and it is suitable for both negative and positive earth bikes.

The package includes a fused harness with non reversible plug for permanent fitting to the motorcycle. Supplied also are 4 x 4m cables to facilitate quick connection of the charger to the bike: “wheel in place, snap on the cable connector and walk away”.

The control unit takes the feed from the solar panel to 4 separate charging regulators.

Each regulator is current limited, so plugging in a half flat battery to one unit cannot rob the charge current from the other batteries on charge. There are led indicators to show “on charge” and “float voltage”.

· Extends battery life by avoiding deep discharge.

· Quick and easy to connect: no alligator clips, no seats or side covers to remove and refit.

· Easy to install harness: if you can change a battery, you can fit the harness.

· Safe to use: fuse protected harness eliminates potential for accidental shorting of terminals and protects the bike in the event the supply cable is damaged.

· Frees up mains power outlets.

· Robust cable with external sheath for protection from mechanical damage.

As a restorer of British motorcycles for the last forty years, I was fortunate to be introduced to Chris when I was looking for someone who understood vintage British electrics. Over the years I have handed Chris some curly jobs and I have never been disappointed with the results. His workmanship, honesty and knowledge of his profession is second to none. I have no hesitation in recommending his services.

- Geoff Hinspeter.